Revolutionary Clean. Proven Results. Brought to you by Pesumati Trade

Pesumati Trade is the official distributor of Kemaro AG autonomous cleaning robots in Estonia. As experts in the cleaning industry, we know what really works, and Kemaro is the solution that will transform industrial cleaning forever. This isn’t just a cleaning robot – it’s an investment in efficiency that frees up your employees for more valuable tasks.

Automate Your Industrial Cleaning & Boost Your Bottom Line

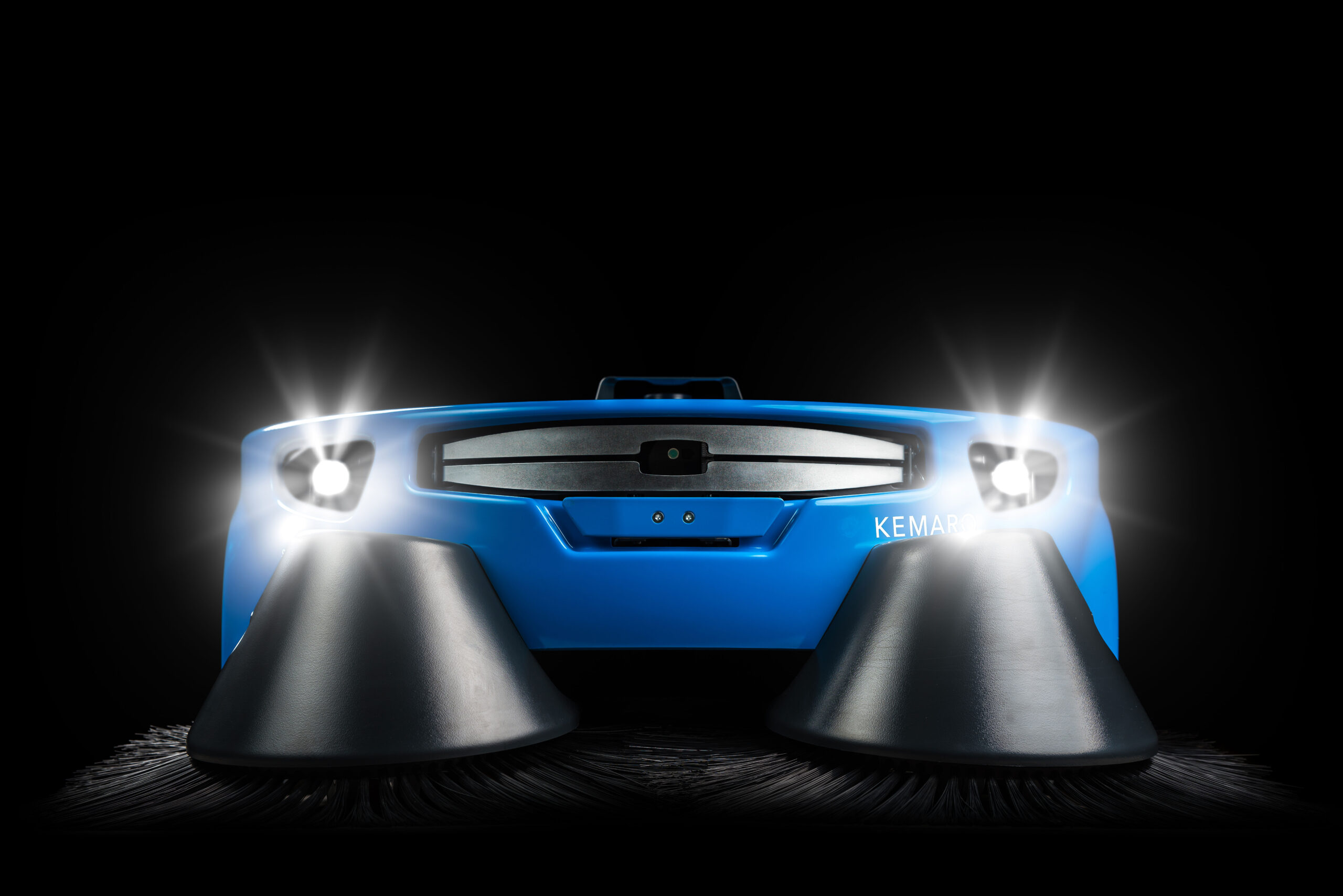

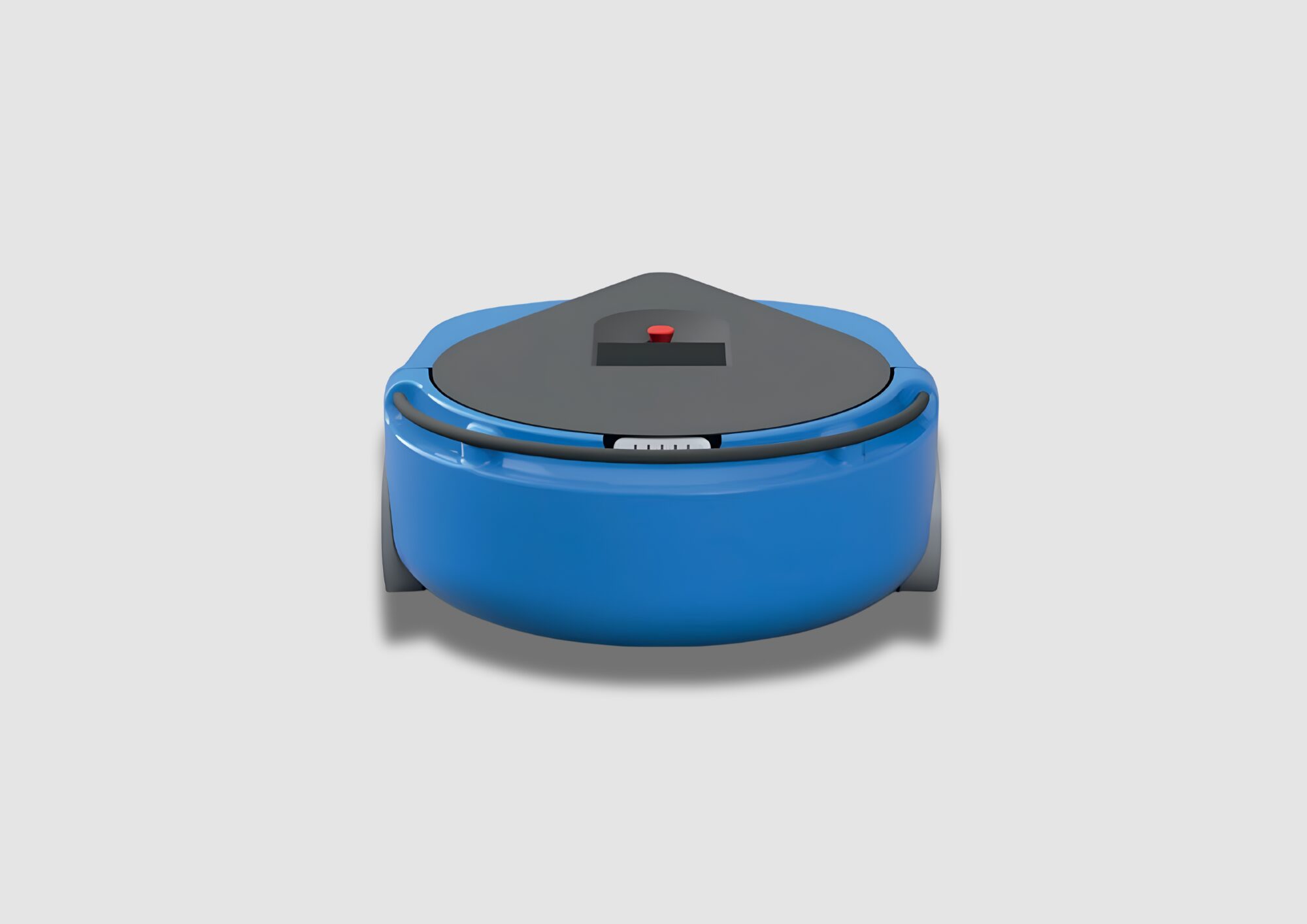

Engineered for complete autonomy, the Kemaro K900 is an industrial cleaning robot that marks a paradigm shift in facility maintenance. Purpose-built to navigate the complex topographies of modern workplaces — from sprawling warehouses and dynamic production lines to restricted hazardous areas — it systematically eliminates debris and contaminants. This meticulous approach not only upholds a superior standard of hygiene but also tangibly enhances operational safety and workflow.

Find the Right Industrial Cleaning Robot for Your Needs

Kemaro cleaning robots offer innovative solutions for various surfaces and needs. Regardless of the size of the cleaning area or the complexity of the work environment, they ensure maximum efficiency, ease of use, and cost-effectiveness. Find the perfect model for your needs.

K900 Gen II TOP

K900 Gen II Smart

K900 Gen II ECO

K900 Wet Environment

K700 Compact

Why Choose the Kemaro K900 Robotic Cleaner?

- The cleaning robot operates continuously and thoroughly, reducing the need for manual labor.

- Efficient cleaning processes help save both, time and staffing costs.

- Removes hazardous glass shards and reduces dust, including from equipment surfaces and between shelves.

- AI-powered navigation with 3D and LiDAR scanning allows the robot to adapt to changes, such as new obstacles or different types of flooring.

- Comes with a remote control that enables manual steering, even into restricted zones during the mapping process.

Built for Any Industrial Environment – From Warehouses to Hazardous Areas

The Kemaro K900 meets the most diverse needs, making it suitable for both specific and complex tasks.

Manufacturing Companies and Processing Industry

The K900 is ideal for factories, where its compact and robust design allows it to navigate tight spaces, such as under low conveyor belts. There is no need to stop production while the robot operates—it effectively removes dust and various types of debris, such as sawdust, glass, or metal fragments, and ensures clean surfaces even in wet conditions.

Warehousing

The K900 is the only autonomous cleaning solution on the market for storage and retrieval systems. Its low weight ensures it has no problems with weight restrictions on floors and it has a highly developed navigation algorithm. It can cover areas of up to 40’000 m² in just a few hours.

Hazardous areas

Interim storage facilities for radioactive waste, high security wings or zones with strong temperature fluctuations. The K900 can function in areas that are potentially dangerous for people. The Hardware and software is designed and built to withstand numerous hazards.

Special applications

There are many and varied special applications for the K900, with new uses being added every day. Examples, including bottling plants and railway depots, demonstrate that the K900 can also function in very dirty and wet environments.

Your Investment Secured: A 3-Year / 5,000-Hour Warranty

KEMARO AG stands by its promises – by choosing KEMARO, you are choosing Swiss engineering quality, reliability, and precision. The KEMARO K900 robot is built to last.

The new warranty terms are effective immediately and apply retroactively to all GEN II models:

-

The warranty covers all components, excluding wear parts.

-

The warranty is valid if maintenance is carried out by KEMARO or an official KEMARO sales partner.

-

The warranty is valid for 3 years or up to 5,000 operating hours – whichever comes first.